Fully automatic mosquito coil making machine was developed by our company in 2006 .This products adopted such advanced systems as the servo motor used by precise machine tool and big tonnage high speed hydraulic system.Mitsubishi PLC main control circuit and intellectualized touch screen operating panel,It has the advantages of tight and reasonable structure,stable operation,precise positioning of chain and better permeability of mosquito coil.The equipment only need four person to operate,which improved the automatic degree and work efficiency,reduce the labor intensity of workers and greatly improve the working safety

Mosquito Coil Making Machine

The device is designed for all hydraulic equipment. Photo electric at the beginning of the usage of the PLC controller, automatic machines, simples structure, easy operation and maintenance, high performance, easy mold replacement, cylinder working stroke is short.

Mosquito Coil Making Machine Feature

1. Raw material: charcoal powder, starch powder,wood powder etc.

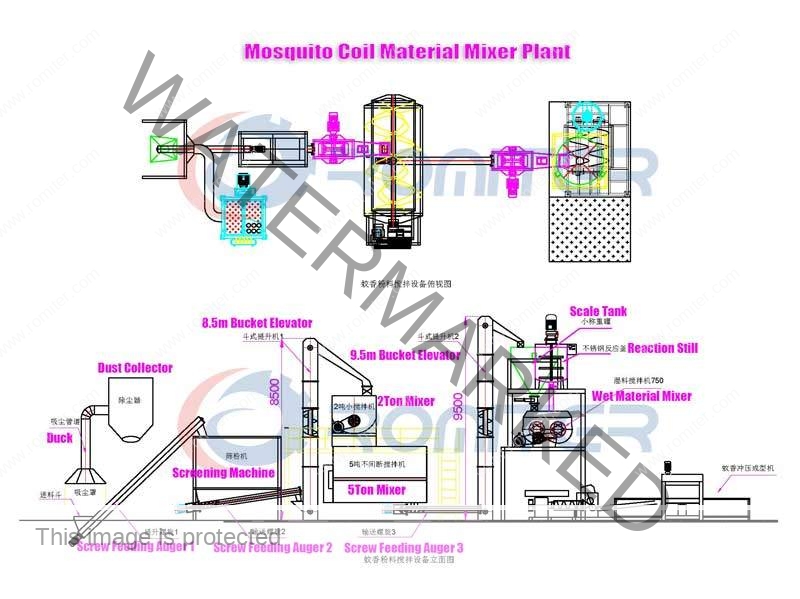

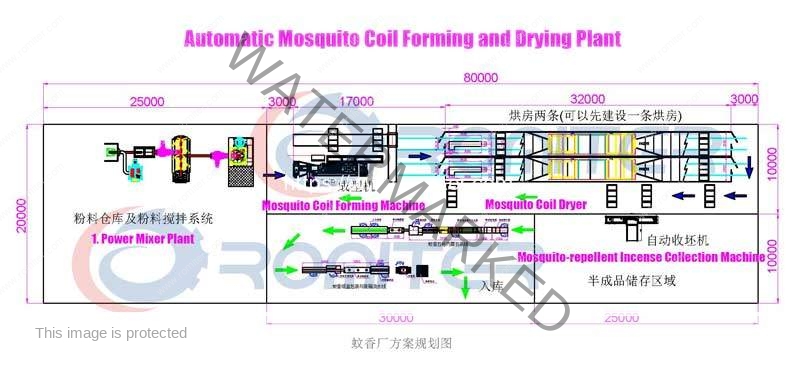

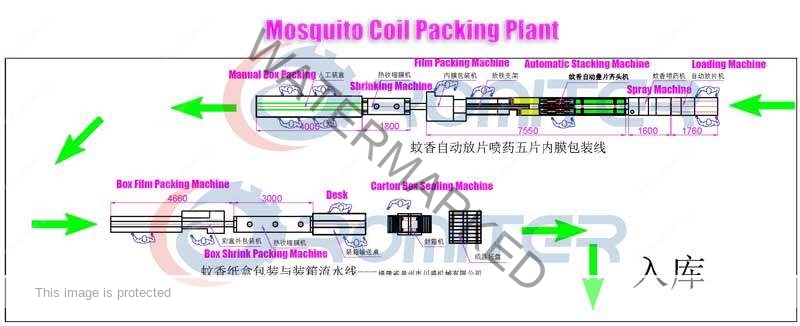

2.working system:raw material mixer- coil forming machine-drying machine-spraying machine-packing machine-inspect -packing-stock

3. Need machine: big mixer, small mixer, broth mixer, forming main machine, elevator (drying machine),drying stove ( built by yourself ),putting machine, spraying machine, packing machine.

Specification

- Model: RMMC

- Capacity: 22680pcs/ h (in 18-mode as an example)

- Motor total power: 27.65KW

- Operator: 4 people

- Sieve plate size: 900mmx450mmx40mm

Mosquito Coil Production Line mainly include powder mixer plant, mosquito coil forming and drying plant, mosquito coil packing plant