Thermoforming Packing Machine is used for thermoforming container, automatic filling, vacuum packing application, which can be used for foodstuff, meat product, garden stuff, pickles, chilled meat, medical product, butter, jam, juice and cheese.

Table of Contents

Advantage Feature

- Main part of the machine is made of stainless steel, that greatly improves the corrosion resistance of the equipment.

- Modular moulds are applied that can be replaced easily and the machine can be used for multiple purposes.

- Both thermoforming mould and sealing mould are equipped with water cooling system.

- German BUSCH vacuum pumps with high extreme degree of vacuum and performance are fitted.

- OMRON PLC, touch screen & servo motor are used with reliable performance and ease of operation.

- Schneider or ABB protection relay & air switch are with long service life and good application.

- With special holding chains, the packaging machine is applicable for extending and moulding of flexible film or rigid film of different thickness for special purpose packaging.

- With advanced punching cutting systems, the machine’s replacement operation is more convenient.

- There is a scrap and waste recycling system to help maintain environmental cleanness.

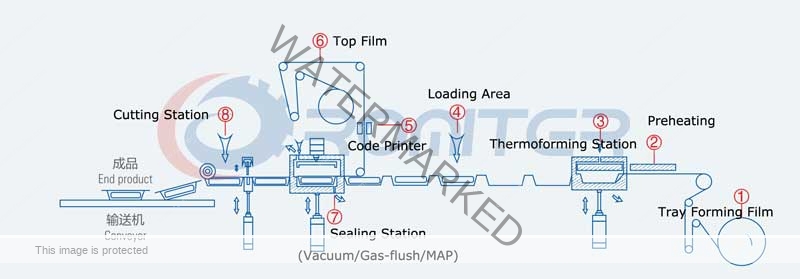

Working Processing

After-Sale Service

- We guarantee machine in good and fast after service for one year, and offers maintainance service for life!

- During the warranty period, any parts damaged or broken, we will courier the spare parts to you within seven days and courier fee at the purchaser account.

- If any problem with the machine, we will try to solve the problem by mail or phone. if e-mail or on the phone still not solved, we will dispatch engineer to your side to fix the problem.

Parameter Table

| Model | RM-390H | RM-490H | RM-420S | RM-390P RM-390P-D |

| Bottom Film Width | 390mm | 490mm | 422mm | 390mm |

| Top Film Width | 380mm | 480mm | 396mm | 360mm |

| Thermoforming Area | 345*216mm | 445*300mm | 390*300mm | 335*175mm |

| Depth Range | 50mm(Max) | 50mm(Max) | 80mm | 11-20mm(max) |

| Speed | 4-5 cycles/min | 4-5 cycles/min | 6-7 cycles/min | 6-8 cycles/min |

| Film Type | Hard Film | Hard Film | Soft Film | Hard Film |

| Addition Function | Air Injection | Air Injection | Vacuum Packing | Air Injection |

| Cutting Type | Knife Cutting | Knife Cutting | Knife Cutting | punching cutting |

| Electrical Specifications | 3 phase 380V/50HZ(Customzied Available) | |||

| Electrical Power | 10-20KW | |||

| Pneumatic Consumption | 80-100L/min, 7bars | |||